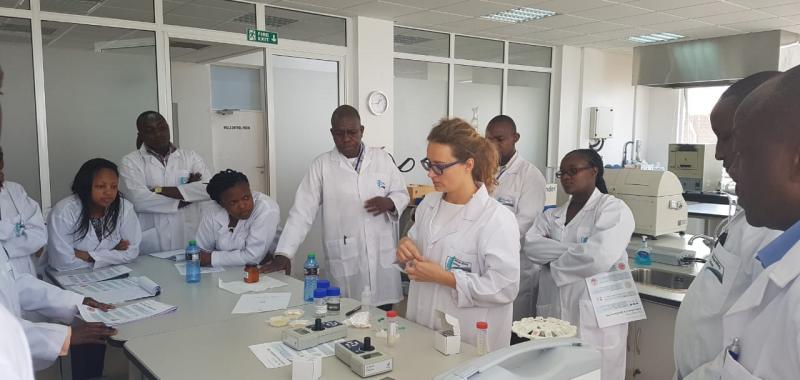

In lower-resource settings, ensuring the effectiveness of food fortification programmes presents significant challenges. Traditional monitoring methods are often complex, expensive, and reliant on stable power, hindering their accessibility and implementation.This creates a compliance gap where producers struggle to verify their practices and regulators lack efficient enforcement tools. The result? Eroded trust in the entire system, leaving consumers unsure about the nutritional value of fortified foods and undermining the intended health benefits.

Ultimately, this ineffectiveness leaves over two billion people vulnerable to micronutrient deficiencies, impacting child development, health outcomes, and tangible Gross Domestic Product (GDP) losses of up to 11 % annually. Addressing these challenges in food control monitoring is crucial to unlock the full potential of fortification programmes and deliver their life-changing impact to those who need it most.